Pioneers in blasting abrasives and

blasting process optimisation.

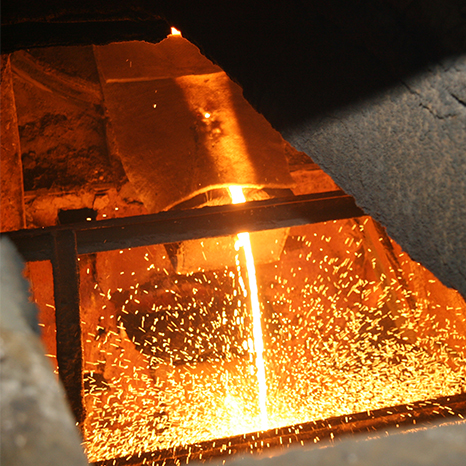

For more than 50 years, Metalltechnik Schmidt has seen itself as a supplier of high-quality abrasives and a driver of innovative techniques in the blasting process. The rapid economic ascent, right at the beginning of the company’s history, is due to the resounding success of FERROSAD, a low-carbon steel blasting abrasive with very high stability. Over time, in addition to FERROSAD, other innovative abrasives such as the aluminium granulate ALUSAD and practical additional products such as the MTS-3000 magnetic floor cleaner have been developed. Today, Metalltechnik Schmidt produces in three-shift operation and supplies its high-quality abrasives to the automotive industry, foundries, rolling mills and many other industries worldwide.

Milestones in the company history.

1958

FERROSAD

Steel abrasive

1967

Foundation

Metalltechnik Schmidt

1968

New building

Abrasives plant

1992

Expansion and renewal

of the smelting capacities

1998

Expansion of

production capacities

2004

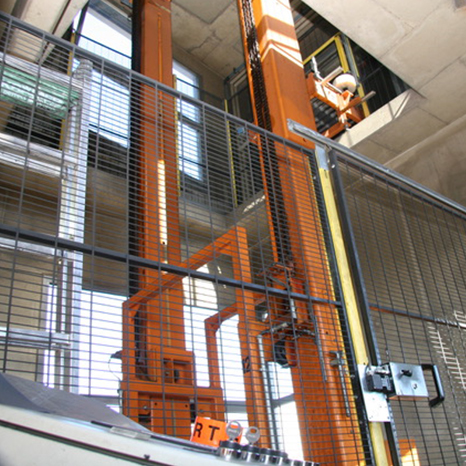

New building

High-bay warehouse

2007

Renewal

of the smelting technology

2008

Quality Management System

ISO 9001

In this year, the processes already converted to ISO 9001 were successfully certified.

2010

Renewal

of the production technology

2012

Energy Management System

ISO 50001

In addition to the already successful certification of ISO 9001 quality management, certification of the ISO 50001 energy management system was also successfully introduced at METALLTECHNIK SCHMIDT GMBH & CO. KG in 2012.

2017

Environmental Management System

ISO 14001

In 2017, certification of the ISO 14001 environmental management system was also successfully introduced at METALLTECHNIK SCHMIDT GMBH & CO. KG.

We see ourselves as part of your process chain.

Metalltechnik Schmidt GmbH & Co. KG . Schulstraße 41 . D‑70794 Filderstadt . Phone: +49 711 779 907–0 . Email: sales@ferrosad.com