A blasting abrasive is more than a blasting agent. We call it Strahlkraft.

Alloy, shape, sieving – each individual feature ultimately determines the quality of the blasting process. A good choice of abrasive takes all aspects into account. Only then does it fit optimally into your value-added chain and achieve the desired effect. Simply because the results of the blasting process have a long-term influence on the quality of many products.

That’s why we first look at the perfect surface from the customer’s point of view. How does the blasting process affect the durability of the subsequent surface coating? What degree of purity must be achieved by the blasting process? Our drive is always the individually perfect surface, a round result that is much more than a superficial matter. We call it Strahlkraft.

Our product advantages

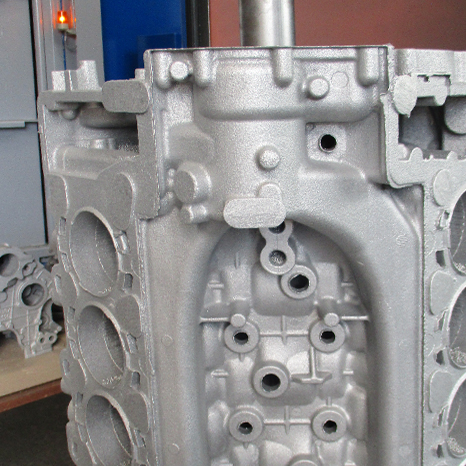

Metalltechnik Schmidt has a wealth of experience in all areas of the blasting process with metal alloys. This expertise flows consistently into every single one of our products. That is why we also guarantee that the blasting process is efficient from the very beginning. Whether low-carbon steel abrasive or ferrite-free aluminium abrasive, spherical material (steel shot) or, angular grain (steel grit), there are some very concrete advantages that speak for Metalltechnik Schmidt products, which, seen as a whole, multiply to a decisive competitive advantage.

OPTIMALLY ADAPTED TO YOUR APPLICATION:

BLASTING TESTING IN OUR IN-HOUSE BLASTING EQUIPMENT IN THE MTS TECHNICAL CENTRE

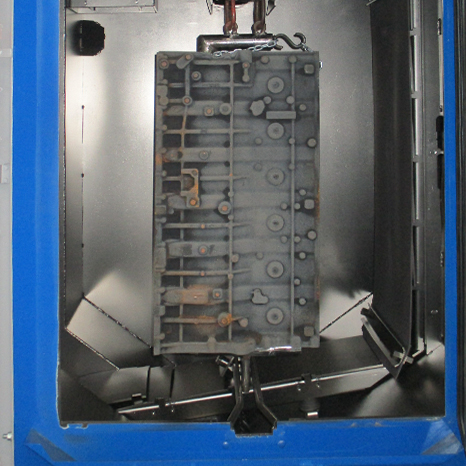

As a competent partner we are happy to perform blasting trial for initial sampling. In our new technical centre we have two modern overhead conveyor blasting systems. One unit is available specifically for blasting with steel abrasives, the other for ferrite-free blasting. This allows you to assess the high quality of our products under realistic conditions without having to charge your own plant.

See also the article:

“Blasting abrasive for aluminium and magnesium casting”

“Electrochemically neutral blasting of aluminum”

Metalltechnik Schmidt GmbH & Co. KG . Schulstraße 41 . D‑70794 Filderstadt . Phone: +49 711 779 907–0 . Email: sales@ferrosad.com ![]()

![]()

![]()