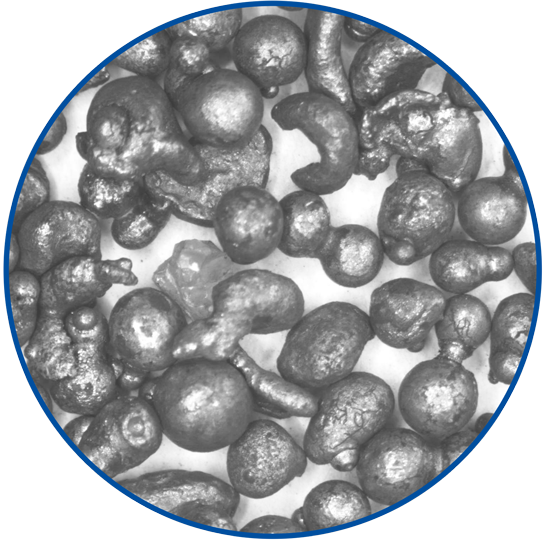

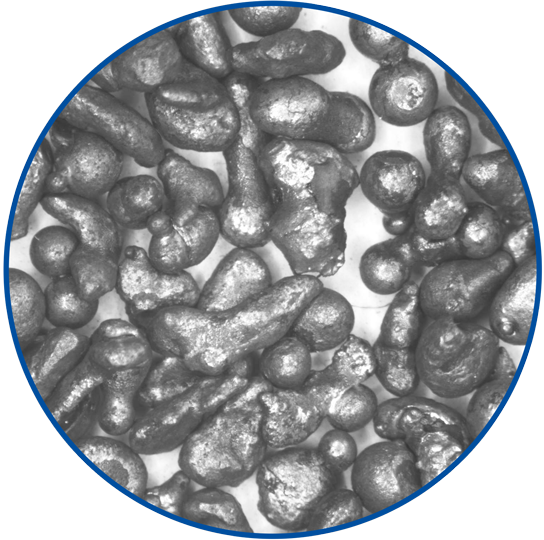

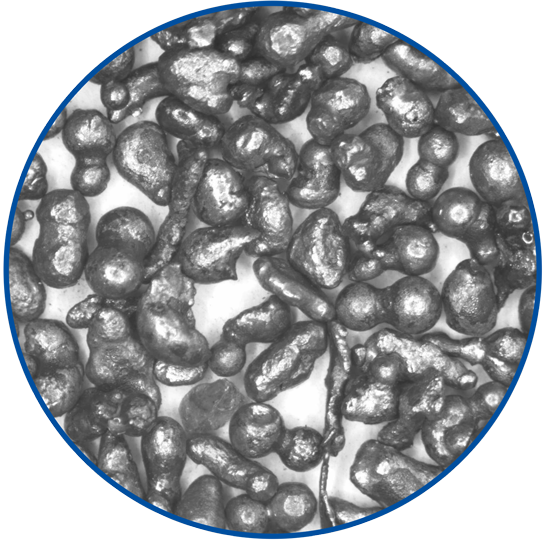

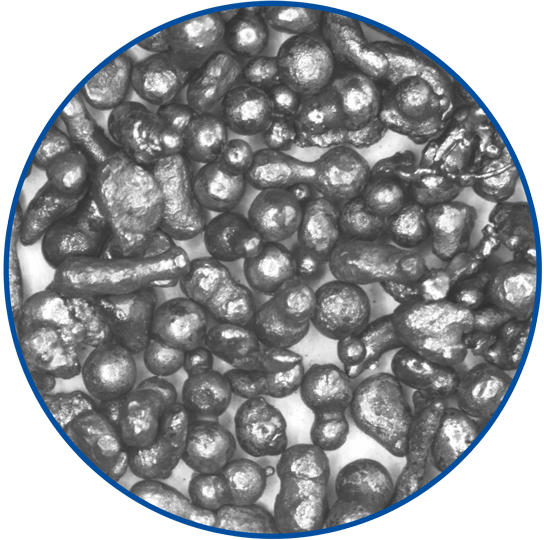

Low carbon steel abrasive

Due to its geometry, our FERROPLUS abrasive offers significantly more abrasiveness. This can be advantageous for certain applications where, for example, greater roughness depth is desired for subsequent coating. As a low-carbon abrasive, it has the same chemical analysis and the resulting bainitic structure as FERROSAD.

This means that the same positive properties are also achieved in the blasting process with this abrasive medium.

Application

Cleaning blasting in centrifugal and compressed air/open air blasting systems.

FP 13

2.80 mm

FP 16

2.00 mm

FP 20

1.40 mm

FP 24

1.00 mm

Chemical analysis:

C approx. 0.10 %

Si approx. 0.15 %

Mn approx. 1.15 %

Fe > 98 %

Hardness: HV 1(ISO 11125–3, ISO 6507)

in new grain: 390 — 430

in operation: 440 — 480

Bulk density:

FP 13: 3.80 – 4.20 kg/dm³

FP 16: 4.00 – 4.30 kg/dm³

FP 20: 4.00 – 4.30 kg/dm³

FP 24: 4.00 – 4.30 kg/dm³

Delivery form:

Packed in PE bags of 20 kg each. The shipment is made on Euro pallets in units of 1000 kg (50 bags @ 20 kg). The pallet is protected with a cardboard box and shrink-wrap foil. Or in1000 kg BigBag on Euro pallet protected by shrink-wrap.

Or in barrels (2 pces. @ 800 kg ea.) on 1 Euro pallet and protected by shrink-wrap.

See also the article:

“More economical with low-carbon steel abrasive”

Magnetic floor cleaner MTS-3000

For more cleanliness in your production.

MTS Technical Centre

We test in our own blasting facility.

Metalltechnik Schmidt GmbH & Co. KG . Schulstraße 41 . D‑70794 Filderstadt . Phone: +49 711 779 907–0 . Email: sales@ferrosad.com