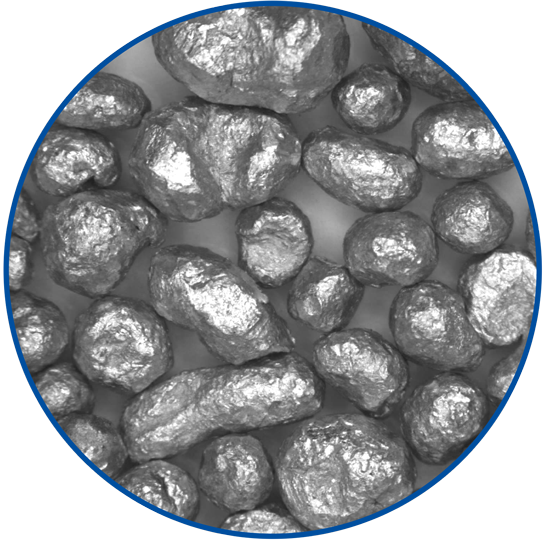

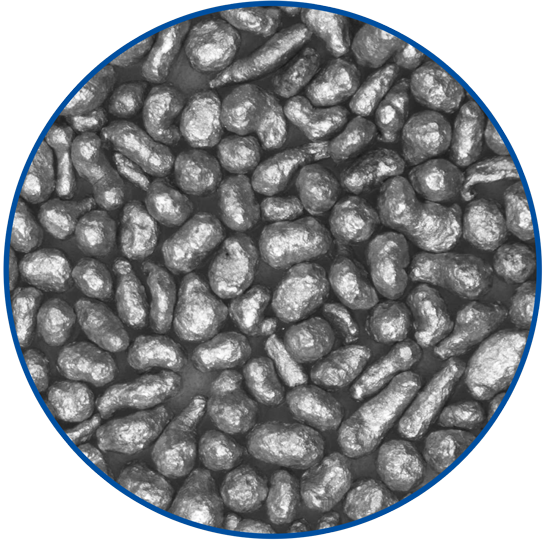

Al 30

1.60 — 3.00 mm

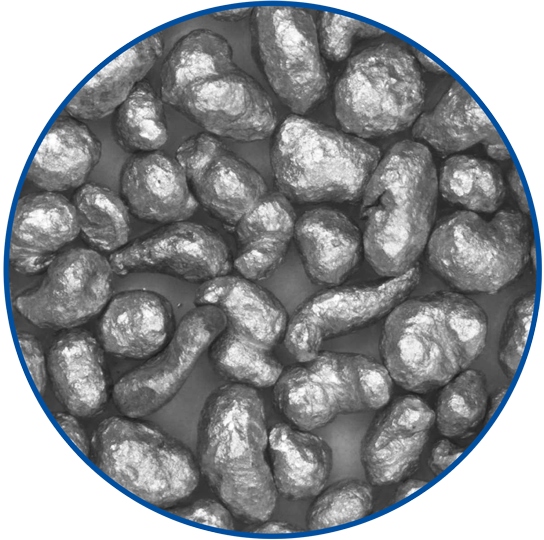

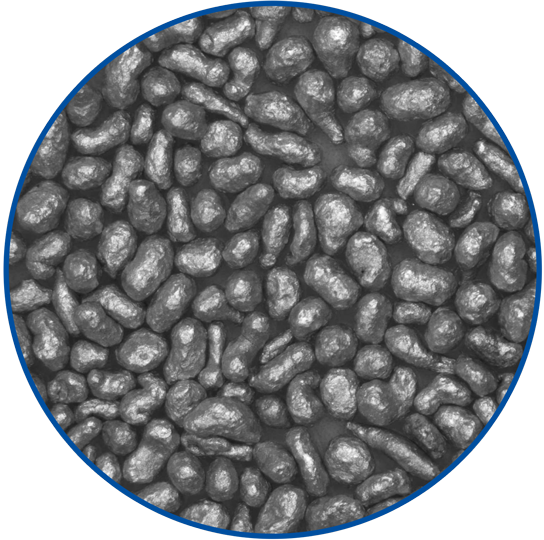

Al 25

1.00 — 2.50 mm

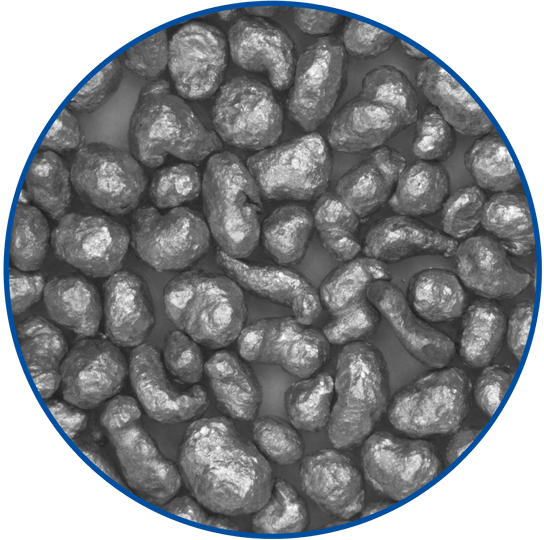

Al 20

0.80 — 2.00 mm

Al 15

0.80 — 1.50 mm

Al 10

0.30 — 1.00 mm

| Chemical analysis: | |

| Si Fe Cu |

approx. 10.5 % max. 0.15 % max. 0.03 % |

| Hardness: HV 0.3 (ISO 11125–3/ISO 6507) |

|

| in new grain: 90 — 100 in operation: 140 — 160 |

| Bulk density | |

|

1.4 — 1.6 kg/dm³ |

| Grain sizes: | |

| AL 30 1.60 — 3.00 mm AL 25 1.00 — 2.50 mm AL 20 0.80 — 2.00 mm AL 15 0.80 — 1.50 mm AL 10 0.30 — 1.00 mm |

| Areas of application: | |

|

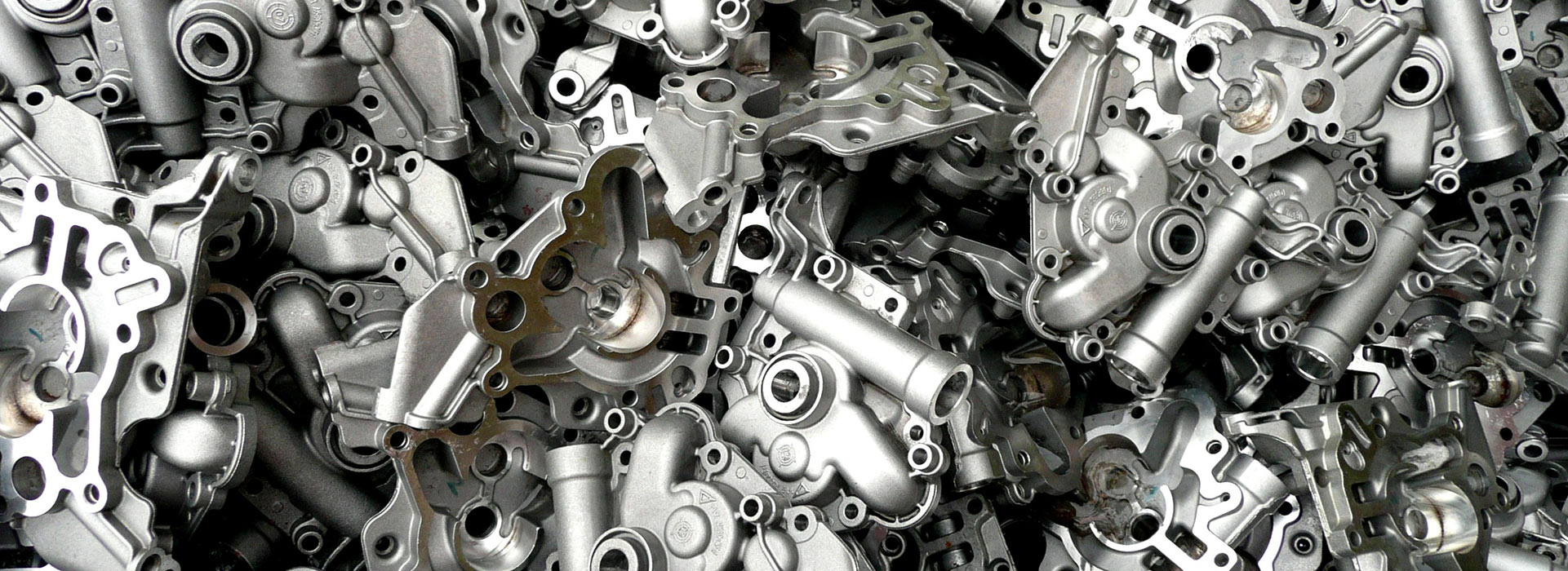

The aluminium blasting agent ALUSAD is particularly suitable for electrochemically neutral blasting for desanding aluminium sand casting or for deburring aluminium die casting or aluminium forging blasting. Furthermore, the ALUSAD abrasive is suitable for the cleaning blasting of magnesium castings. |

|

| Delivery form: | |

| Packed in PE bags of 20 kg. each. Shipment is made on Euro pallets in units of 500 kg (25 bags @ 20 kg. each). The pallet is protected with a cardboard box and shrink-wrap foil. |

Chemical analysis:

Si approx. 10.5 %

Fe max. 0.15 %

Cu max. 0.03 %

Hardness: HV 0.3

(ISO 11125–3/ISO 6507)

in new grain: 90 — 100

in operation: 140 — 160

Bulk density

1.4 — 1.6 kg/dm

Grain sizes:

AL 30 1.60 — 3.00 mm

AL 25 1.00 — 2.50 mm

AL 20 0.80 — 2.00 mm

AL 15 0.80 — 1.50 mm

AL 10 0.30 — 1.00 mm

Applications:

The aluminium blasting medium ALUSAD is particularly suitable for electrochemically neutral blasting for desanding aluminium sand casting or for deburring aluminium die casting or aluminium forging blasting. Furthermore, the ALUSAD abrasive is suitable for the cleaning blasting of magnesium castings.

Delivery form:

Packed in PE bags of 20 kg. each. Shipment is made on Euro pallets in units of 500 kg (25 bags @ 20 kg. each). The pallet is protected with a cardboard box and shrink-wrap foil.

See also the article:

“Blasting abrasive for aluminium and magnesium casting”

“Electrochemically neutral blasting of aluminum”

Metalltechnik Schmidt GmbH & Co. KG . Schulstraße 41 . D‑70794 Filderstadt . Phone: +49 711 779 907–0 . Email: sales@ferrosad.com